Tesiwaju Extrusion Machinery

Awọn anfani

1, ibajẹ ṣiṣu ti ọpa ifunni labẹ agbara ija ati iwọn otutu ti o ga julọ eyiti o yọkuro awọn abawọn inu inu ọpá funrararẹ patapata lati rii daju pe awọn ọja ikẹhin pẹlu iṣẹ ṣiṣe ọja to dara julọ ati deede iwọn to gaju.

2, bẹni preheating tabi annealing, awọn ọja didara ti o dara ni ibe nipasẹ ilana extrusion pẹlu agbara agbara kekere.

3, pẹlu ifunni ọpá iwọn ẹyọkan, ẹrọ naa le ṣe agbejade iwọn titobi pupọ ti awọn ọja nipa lilo awọn ku oriṣiriṣi.

4, gbogbo laini ni irọrun ati iyara ṣiṣẹ laisi eyikeyi iṣẹ eru tabi idoti lakoko extrusion.

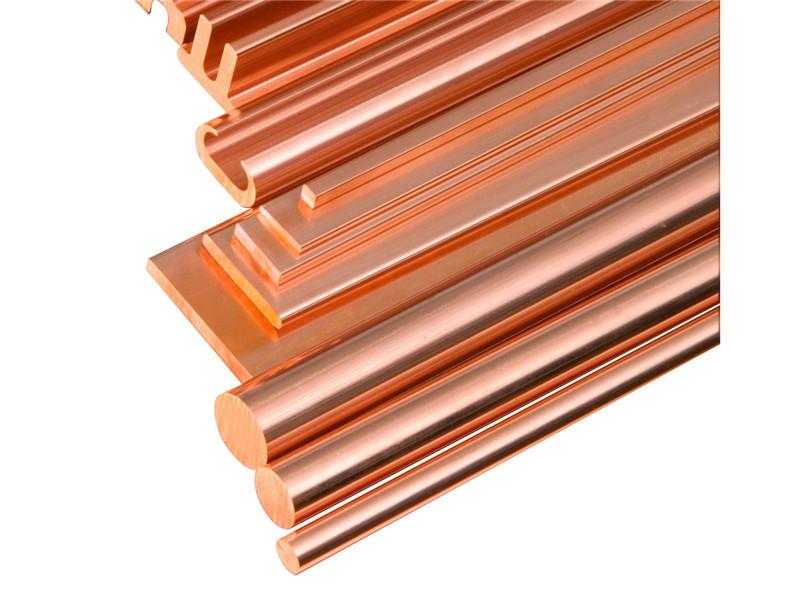

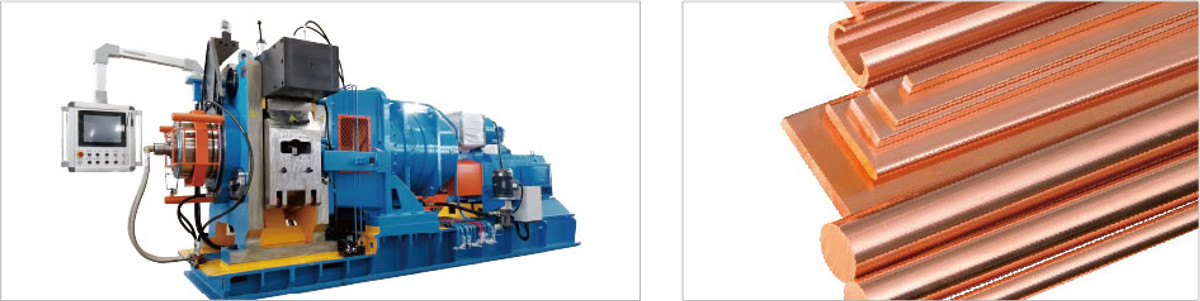

Ejò opa ono

1.Lati ṣe Ejò alapin onirin, kekere Ejò busbar ati yika waya

| Awoṣe | TLJ 300 | TLJ 300H |

| Agbara mọto akọkọ (kw) | 90 | 110 |

| Opa ono dia. (mm) | 12.5 | 12.5 |

| O pọju. iwọn ọja (mm) | 40 | 30 |

| Alapin Waya Cross-Sectional | 5-200 | 5-150 |

| Ijade (kg/h) | 480 | 800 |

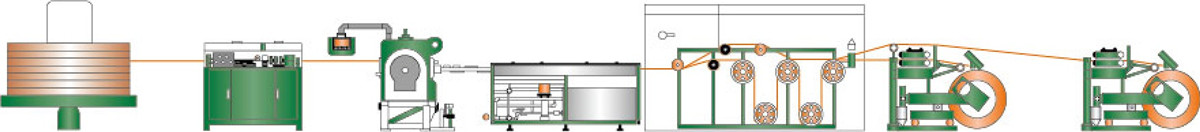

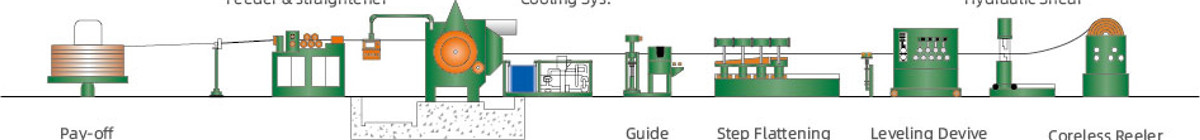

Production Line Layout

Pay-pipa Pretreatment Extrusion Machine itutu Sys. Onijo Ya-soke Machine

2.Lati ṣe Ejò busbar, Ejò yika ati Ejò profaili

| Awoṣe | TLJ 350 | TLJ 350H | TLJ 400 | TLJ 400H | TLJ 500 | TLJ 630 |

| agbara motor akọkọ (kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| ono opa dia. (mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| o pọju. iwọn ọja (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| opa ọja dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| agbegbe agbekọja ọja (mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| àbájáde (kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

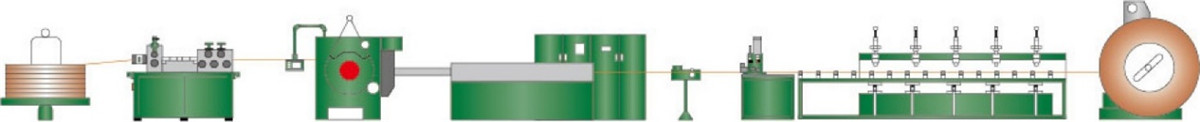

Production Line Layout

Sanwo-pipa atokan & straightener Extrusion Machine Cooling Sys. Ipari Counter ọja ibujoko Ya-soke Machine

3. Lati ṣe Ejò busbar, Ejò rinhoho

| Awoṣe | TLJ 500U | TLJ 600U |

| agbara motor akọkọ (kw) | 355 | 600 |

| ono opa dia. (mm) | 20 | 30 |

| o pọju. iwọn ọja (mm) | 250 | 420 |

| o pọju. iwọn to sisanra ratio | 76 | 35 |

| sisanra ọja (mm) | 3-5 | 14-18 |

| àbájáde (kg/h) | 1000 | 3500 |

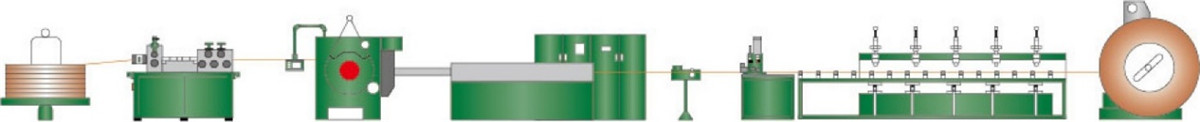

Production Line Layout

Ejò alloy opa ono

Nbere fun adaorin commutator, idẹ òfo, ọpá bàbà phosphor, rinhoho fireemu asiwaju, Reluwe olubasọrọ waya ati be be lo.

| TLJ 350 | TLJ 400 | TLJ 500 | TLJ 630 | |

| ohun elo | 1459/62/63/65 idẹ cu/Ag (AgsO.08%) | Ejò phosphor (Pso.5%) cu/Ag (AgsO.3%) | Ejò magnẹsia (MgsO.5%) irin Ejò (Feso.l% | Ejò magnẹsia (MgsO.7%)/Cucrzr |

| ono opa dia. (mm) | 12/12.5 | 20 | 20 | 25 |

| o pọju. iwọn ọja (mm) | 30 | 150 (okun idẹ fadaka) | 100(okun fireemu asiwaju:) | 320 |

| opa ọja dia.(mm) | phosphor Ejò: 10-40 | magnẹsia copperrod: 20-40 | magnẹsia copperrod: 20-40 | |

| àbájáde (kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

Production Line Layout

Sanwo-pipa atokan & straightener Extrusion Machine Cooling Sys. Ipari Counter Ya-soke Machine

Aluminiomu opa ono

Nbere fun okun waya alapin, ọpa ọkọ akero, ati oludari profaili, tube yika, MPE, ati Awọn tubes PFC

| Awoṣe | LLJ 300 | LLJ 300H | LLJ 350 | LLJ 400 |

| agbara motor akọkọ (kw) | 110 | 110 | 160 | 250 |

| ono opa dia. (mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| o pọju. iwọn ọja onirin alapin (mm) | 30 | 30 | 170 | |

| Ọja onirin alapin Agbegbe agbelebu-apakan (mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| yika tube dia. (mm) | 5-20 | 5-20 | 7-50 | |

| gbigbẹ tube alapin (mm) | - | ≤40 | ≤70 | |

| waya alapin / Ijade tube (kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

Production Line Layout

Pay-pipa straightener Ultrasonic cleaning Cooling Sys onijo Ya-soke Machine

Aworan 217282